REFURBISHED ATTACHMENTS

Whether you purchase one of our refurbished units or you want your own attachment rebuilt, refurbishing is the answer to cutting down on handling equipment costs.

Whatever the type, model, or manufacturer, when you think the time has come to replace your attachments, refurbishing with Canadian Flexible T.M. Inc. is THE SOLUTION.

Before attaching our name to a refurbished unit, we put it through the most complete rebuilding process in the industry to restore it back to its original technical specifications.

We do not ship out attachments, or part of them, to subcontractors or other branches. All the work is done at our premises. We can therefore deliver 2 to 3 times faster than our competitors.

Where other companies replace only if they think it's necessary, we replace all these parts every time: hoses, fittings, bearings, bushings, seals, o-rings and every bolt, big or small. And all attachments go through every one of the following steps:

• The

attachment is cleaned on arrival and all functions are tested before disassembly.

At this point, if any major defects are detected we advise the customer

immediately before we proceed with any additional work, to avoid any surprise

expenses.

• The

attachment is completely disassembled: base, arms, cylinders …

• Every steel component is sandblasted.

• The rotator is disassembled and rebuilt.

• The bearings in the arms or base are replaced.

• The

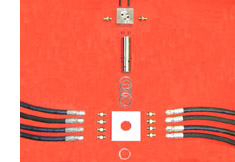

seals in the hydraulic cylinders and hydraulic valves are replaced.

• Roller

bearings and the seals in the drive unit are replaced.

• A

magnetoscopic inspection of every weld is performed at our premises, by

a certified lifting apparel inspector from an independent inspection

firm.

Canadian Flexible T.M. Inc. does not interfere during the processes of magnetoscopic inspection and welding repairs. They are done by independent certified professionals, in order to better protect all parties involved, including our customers and end-users.

• The seals in the revolving unit are replaced.

• New hoses and fittings are installed.

• The attachment is painted according to the customer's selected color.

•

The attachment is reassembled and tested with a pressure tester and a

test bench, to ensure it performs to the standards of the manufacturer.

Every rebuilt attachment comes with a 6 month warranty on parts and labour, with unlimited hours of operation.